The Benefits Of Closed Cell EPS Insulation

There's a reason EPS is overtaking other insulation options...

EPS (Expanded Polystyrene) is an extremely lightweight product that is made of expanded polystyrene beads. Originally discovered by Eduard Simon in 1839 in Germany by accident, EPS foam is more than 98% air.

When compared with commonly used insulating materials such as wood, cardboard, wool etc, polystyrene is the most cost-efficient as well as energy efficient and superior of them all.

Air is a bad conductor of heat, when compared with commonly used insulating materials such as wood, cardboard, wool, fiberglass, etc, EPS is the most cost-efficient and superior of them all. Air is a bad conductor of heat that makes EPS exceptionally good at blocking heat transfer. Its thermal resistance is way above all other insulators.

Small solid plastic particles of polystyrene are made from the monomer styrene. Polystyrene is normally a solid thermoplastic at room temperature that can be melted at a higher temperature and re-solidified for desired applications.

The expanded version of polystyrene is about forty times the volume of the original polystyrene granule.

Uses of Expanded Polystyrene:

Expanded Polystyrene foams are used for a variety of applications because of its excellent set of properties including good thermal insulation, good damping properties and being extremely light weight.

From being used as building materials to white foam packaging, expanded polystyrene has a wide range of end-use applications. In fact, many surfboards now use EPS as the foam core.

Building and Construction:

EPS is inert in nature and therefore does not result in any chemical reactions. Since it will not appeal to any pests, it can be used easily in the construction industry.

It is also a closed cell, so when used as a core material it will absorb little water and in return, not promote mold or rotting.

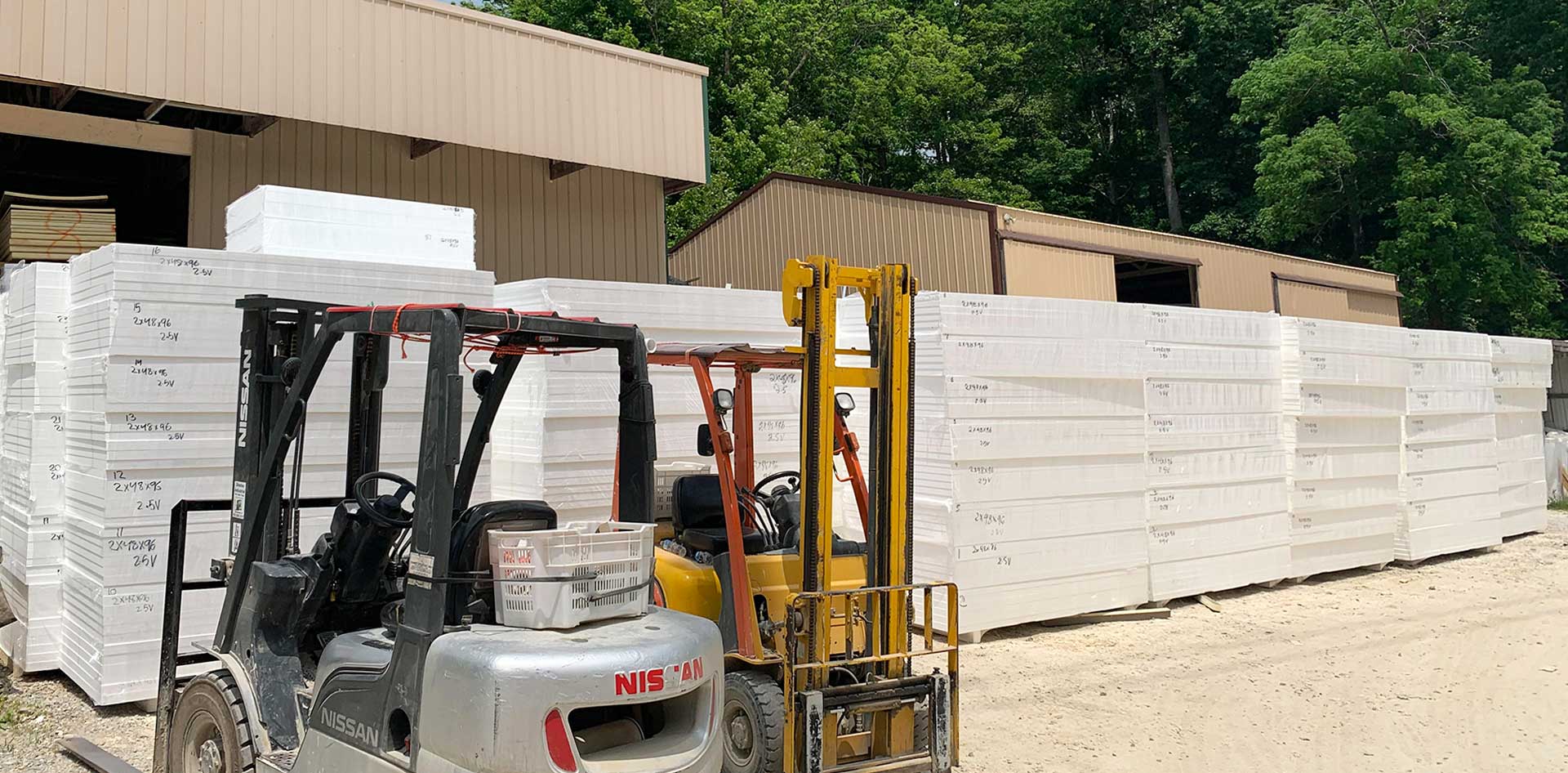

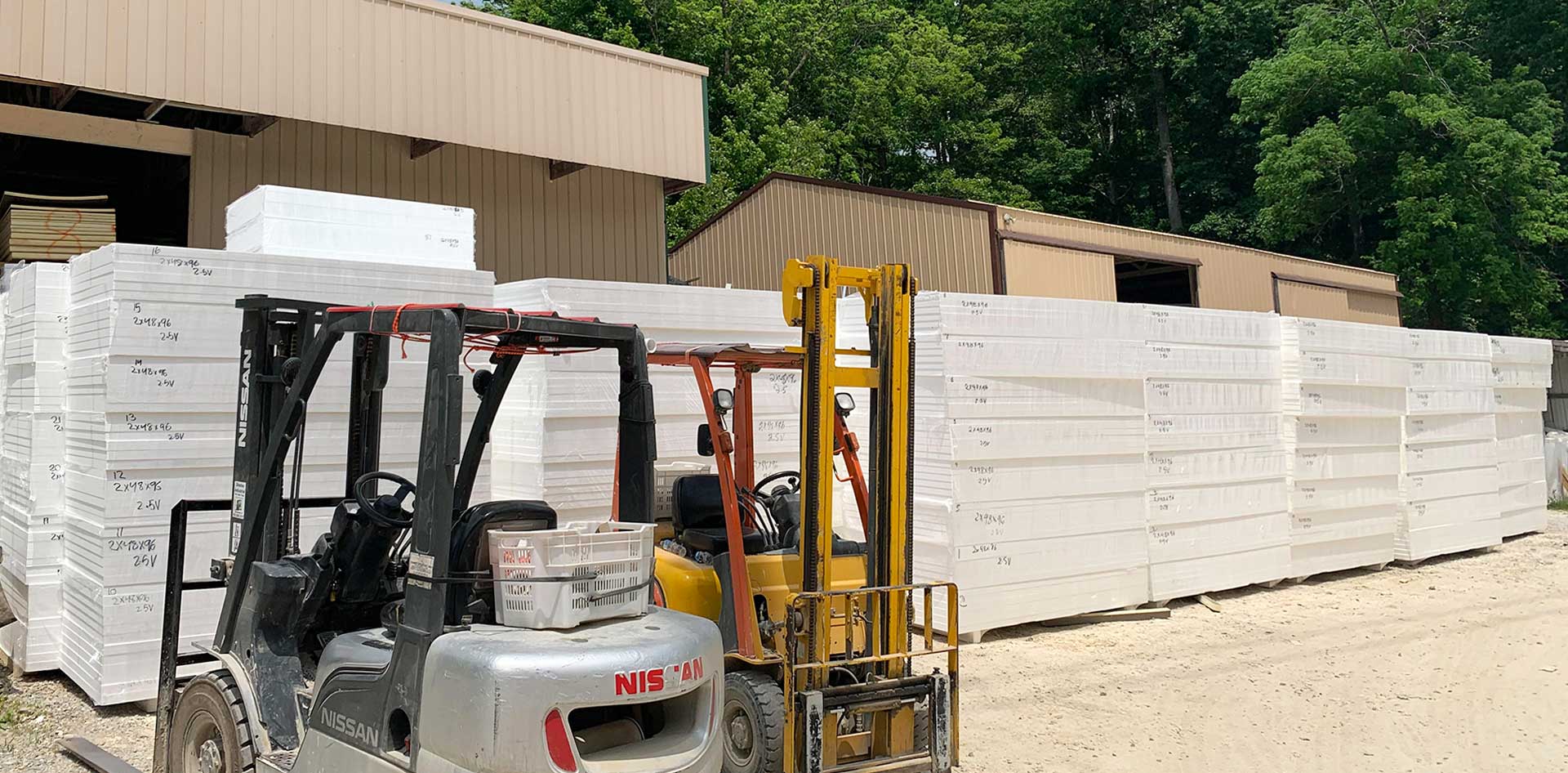

EPS is durable, strong as well as lightweight and can be used as insulated panel systems for facades, walls, roofs, under concrete and much more in building applications.

Packaging:

EPS has shock absorbing properties making it ideal for storing and transporting fragile items such as wines, chemicals, electronic equipment, and pharmaceutical products.

Its thermal insulation and moisture resistant properties are perfect for packaging cooked food as well as perishable items such as seafood, fruit, and vegetables.

Other Uses:

EPS can be used in the manufacture of sliders, model planes, and even surfboards because of its positive strength to weight ratio. The strength of EPS along with its shock absorbing properties makes it effective for use in children’s seats and cycling helmets.

It is also compression resistant, meaning that EPS is ideal for stacking packaging goods. EPS also has applications in horticulture in seedling trays to promote aeration of the soil and what is most always used on any aquatic application such as floating docks, pontoons and more because of it's incredible ability to wick away water opposed to absorbing it like XPS.

Why Is EPS So Advantageous?

- High thermal insulation AND great R-Value.

- INCREASES IN R-VALUE AS TEMPERATURES DROP! That is huge for insulating projects like pole barns or under steel siding.

- Perfect for insulating most applications such as walls, ceilings, concrete, roofs, freezers and moist or wet areas

- Compression resistant, GREAT FOR HIGH DENSITY APPLICATIONS!

- EASILY RECYCLABLE!

- Used on various commercial and residential applications.

- Extremely lightweight.

- Resistant to Moisture.

- Extremely durable.

- Versatile in strength.

- Easily laminated with epoxy resins.

- Manufactured into different shapes, sizes, and compression materials for such an array of applications.

- Lightweight and very portable.

- High shock absorbency characteristics.

EPS IS 100% Recyclable!

Polystyrene is an environment-friendly polymer. It is cent percent recyclable. It is usually recycled and melted to its 1/90th of its original volume. It is then converted to tight bricks.

Polystyrene can also be recycled using liquid hydrocarbons known as Limonene, which can be extracted from citrus fruits. Limonene literally dissolves the foam. These forms of EPS can be transported into factories for reusing. The easiest way to recycle polystyrene is by reusing it for other purposes.

With the highest recycling rates for any plastic and accounting for a non-substantial portion of municipal waste, expanded polystyrene is an environmentally friendly polymer. The EPS industry encourages recycling of packaging material and many large companies are successfully collecting and recycling the EPS.

EPS can be recycled in many different ways such as thermal densification and compression. It can be reused in non-foam applications, lightweight concrete, building products and remolded back into EPS foam.

FUTURE OF EPS IS HERE, DON'T WASTE TIME AND MONEY!

With the considerable number of applications, EPS is being used as a result of its excellent range of properties and extremely energy efficient and especially in colder climates.

The future of the EPS industry is bright and a top choice for insulating your walls, ceilings, crawl spaces, under concrete, roofing, behind siding, walk-in coolers and more.

EPS is cost-effective and the friendly polymer is also best for packaging. EPS is a dominant product with such an array of energy saving options that can't be beat! When going head to head against XPS, Closed Cell EPS will win each category every time.

IN FACT, EPS is long term nearly double the R-Value of XPS (AKA Blue & Pink Board) and wicks nearly 5 times the water away as XPS as well, making it dominate each and every time opposed to XPS.

Call Plywood King for options and let us help steer you in the correct path for longevity, energy efficiency, availability and numerous options all paired with the best discounted pricing in the Midwest!

You might also like

Plywood King offers unbeatable prices on new & reclaimed insulation board. Also offering the best deals & options on residential & commercial steel roofing, pole barn & cold formed steel building packages from our sister company Allsteel Building Supply.

Navigation

All Rights Reserved | Plywood King